Electrospinning

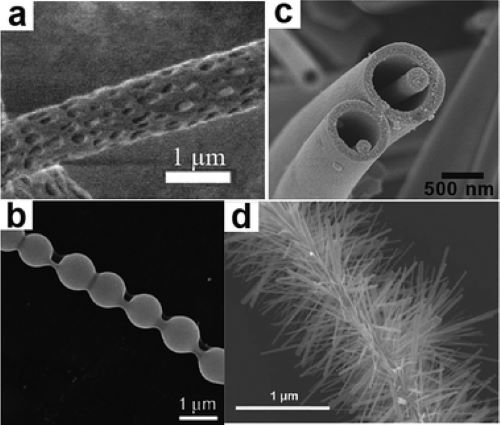

Electrospinning is a versatile technique for producing ultrathin nanofiber scaffolds and membranes, allowing control over diameter, pore size, and properties. These membranes can selectively permeate nano- to micro-scale particles. Traditional ECM models in ‘Organ-on-a-Chip’ systems, often made with Matrigel or other hydrogels, lack mechanical robustness. Our aim is to develop ultrathin, biocompatible membranes with enhanced mechanical strength, permeability, and cell migration capabilities. Additionally, we explore using electrospun membranes as functional barriers in microfluidic systems to regulate flux and capture biomolecules efficiently, enhancing particle concentration and selective permeation.

“Creation of a hybrid scaffold with dual configuration of aligned and random electrospun fibers”

Suk-Hee Park, Min Sung Kim, Byungjun Lee, Jean Ho Park, Hye Jin Lee, Nak Kyu Lee, Noo Li Jeon, and Kahp-Yang Suh, ACS Applied materials & interfaces, 8, 2826-2832 (2016)

“Hybrid microfabrication of nanofiber-based sheets and rods for tissue engineering applications”

Suk-Hee Park, Min Sung Kim, Dasom Lee, Yong Whan Choi, Deok-Ho Kim, and Kahp-Yang Suh, Journal of Laboratory, 18 494-503 (2013)

Digital Lithography

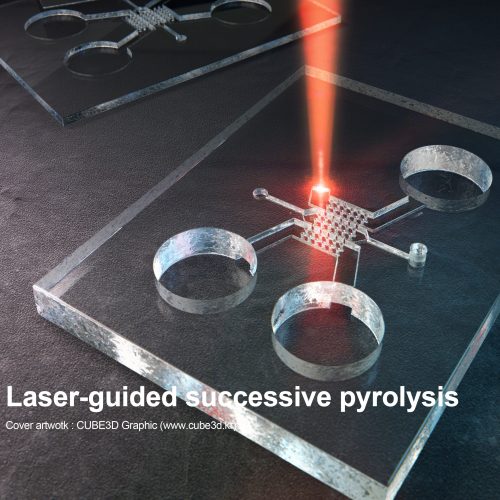

Advancements in manufacturing miniaturized platforms have significantly progressed the field of microphysiological systems. PDMS-based soft lithography is particularly notable for creating intricate microstructures that support natural cell behavior, crucial for organ-level models. However, modifying PDMS designs is challenging due to the complex, time-consuming photolithography process and the slow production of single PDMS molds. To address these issues, continuous laser pyrolysis has been introduced, converting PDMS into silicon carbide and enabling rapid production of high-quality microchannels without the need for on-wafer lithography.

“Monolithic digital patterning of polydimethylsiloxane with successive laser pyrolysis”

Jaeho Shin, Jihoon Ko, Seongmin Jeong, Phillip Won, Younggeun Lee, Jinmo Kim, Sukjoon Hong, Noo Li Jeon & Seung Hwan Ko, Nat. Mater. 20, 100–107 (2021)

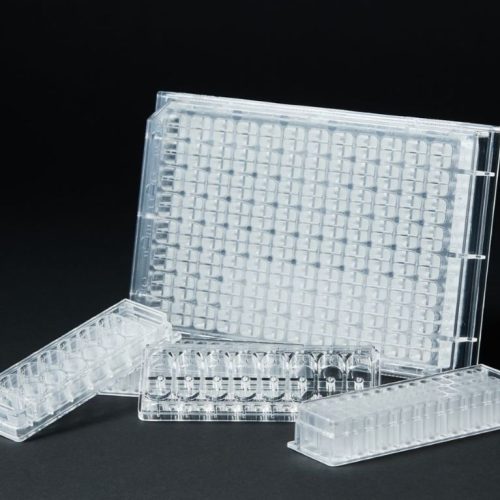

Injection Molding

The fabrication of PDMS-based organ-on-a-chip through lithography is time-consuming and involves multiple processes, from mask creation to chip production using molds. Although it offers high-resolution fine structures, it limits the number of chips produced in one operation and absorbs small molecules, affecting drug or cytokine response verification. Injection molding, on the other hand, allows liquid materials to fill mold gaps, enabling mass production once conditions are established. While it offers lower resolution than lithography and limits design freedom, it supports high-throughput production and overcomes PDMS-related drawbacks by using polystyrene. Additionally, injection molding eliminates user-dependent errors and ensures compatibility with various equipment by adhering to the SBS format.

“Microfluidics within a well: an injection-molded plastic array 3D culture platform”

Younggyun Lee, Jin Woo Choi, James Yu, Dohyun Park, Jungmin Ha, Kyungmin Son, Somin Lee, Minhwan Chung, Ho-Young Kim and Noo Li Jeon, Lab on a Chip(2018)

“High-throughput injection molded microfluidic device for single-cell analysis of spatiotemporal dynamics”

Youngtaek Kim, Jiyoung Song, Younggyun Lee, Sunghyun Cho, Suryong Kim, Seung-Ryeol Lee, Seonghyuk Park, Yongdae Shin, Noo Li Jeon, Lab on a chip, 21, 3150-3158 (2021)

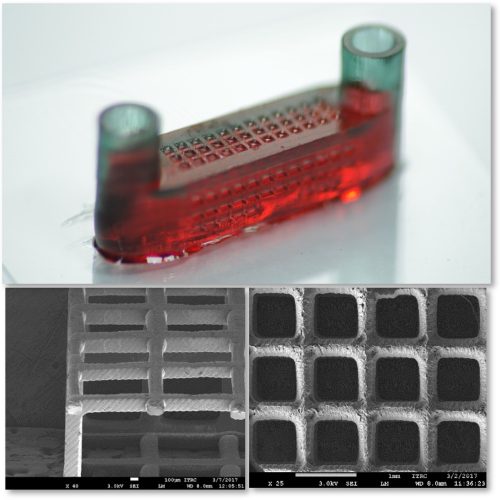

3D Printing

Prototyping microfluidic platform designs using technologies such as photo/soft lithography, micromachining, and electrospinning faces significant limitations, including difficulties in fabricating complex 3D structures, high costs, and issues with structural uniformity and reproducibility. 3D printing, however, overcomes these limitations by using photocurable resin to build structures at the dot or layer level. This technology allows for the rapid construction of intricate 3D structures necessary for microfluidic platforms used in cell culture, reducing production time and costs. Additionally, 3D printing offers high design flexibility and the ability to use a wide range of materials, enabling the creation of specialized prototypes for specific applications.

“3D micromesh-based hybrid bioprinting: multidimensional liquid patterning for 3D microtissue engineering”

Byungjun Lee1, Suryong Kim1, Jihoon Ko, Seung-Ryeol Lee, Youngtaek Kim, Seonghyuk Park, Jiho Kim, Sujin Hyung, Ho-Young Kim, Noo Li jeon, NPG Asia Materials, 14 (1), 1-10 (2022)

“Development of a functional airway-on-a-chip by 3D cell printing”

Ju Young Park, Hyunryul Ryu, Byungjun Lee, Dong-Heon Ha, Minjun Ahn, Suryong Kim, Jae Yun Kim, Noo Li Jeon and Dong-Woo Cho, Biofabrication 11.1, 015002 (2018)